An Overview to Space Logistics & Supply Chain

Humans have always looked up into the night sky and dreamedabout space. For everyday we try our best to soar closer to sun.

After World War II ended, both United States and Soviet joined the ‘space race’ and developed their own space programs. After Soviet launched their first artificial satellite Sputnik 1 in 1957, they successfully sent Lt. Yuri Gagarin to orbit Earth for 108 minutes in 1961. Almost a decade later, the US shocked the world by sending men onto the moon for the first time.

Moon landing was the culmination point of the space race. In1961, US President John F. Kennedy set the national goal as “landing a man on themoon and returning him safely to Earth within a decade.” On July 20 1969, NeilArmstrong historically took “one giant leap for mankind” as he stepped onto themoon.

The moon landing wasn’t a simple operation, especially preparation-wise. It required mankind’s largest supply chain and was reported to have cost USD 25.4 billion (for a single Saturn V launch cost up to USD 375 million or a few billion dollars in today’s money).

To assemble the Saturn V rocket, the largest object to ever leave the surface of the Earth, NASA had to innovate the distribution and logistics process. The boosters had to be transported by a fleet of barges called Palaemon, named after the Greek god who was the protector of ships.

The fleet was made of three 270,000-gallon liquid hydrogen barges, six 105,000-gallon liquid oxygen barges, and two barges for the Saturn V engines; and had traveled through Panama Canal, the Gulf of Mexico, and the Intercoastal Waterway. Before the rockets voyaged into space, their components had already logged thousands of miles over the Pacific and the Atlantic oceans.

The planning and preparation prior to transporting the parts weren’t easy either. The Saturn’s first stage was contracted to Boeing. The company was charged with testing and delivering a completed first stage to NASA in Florida, where the stage would be paired with the second and third stages before launch.

The first stage was assembled outside of New Orleans so every supplier had to be sure to coordinate the development, testing, and delivery of its components on a very tight schedule and under meticulous specifications. There were no personal computers. Fax machines didn’t become popular until the late 1970s. Researchers couldn’t scan images and attach them to e-mails. The modus operandi of the era was an investigation with slide rules, pencils, and paper.

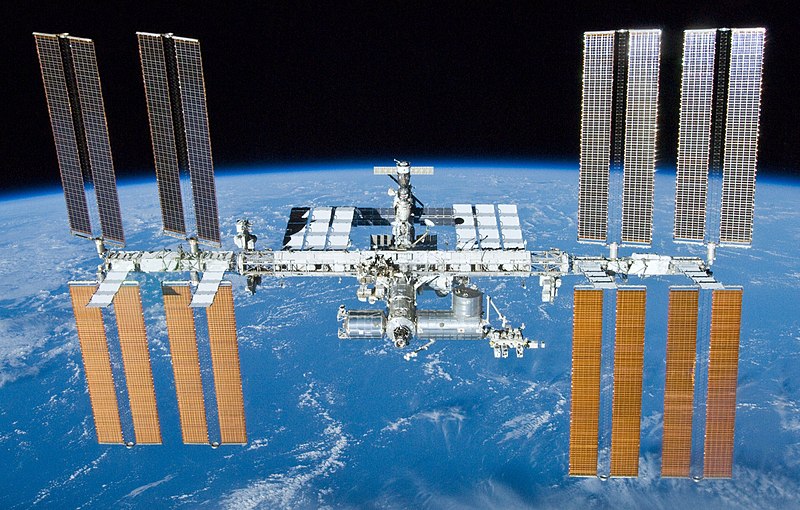

But now that we have the International Space Station (ISS), space is no longer an unknown place to explore. It has become a part of the supply chain. And to integrate the ISS to the chain, Massachusetts Institute of Technology (MIT) research team created the Space Logistics Project. Because unlike Apollo, where everything was carried along in the vehicle, future exploration will have to rely on a complex supply-chain network on the ground and in space.

To send goods directly to the end-point in the outer space would be too costly. Florida Institute of Technology estimated that it would cost around USD 450 million per space mission. Broken down by weight, they predicted that it would cost roughly USD 83,000/pound to transport goods to the moon. By that calculation, just to send a gallon of water off to the moon would cost as much as USD 690,000.

The primary goal of the project is to create interplanetary supply chain management and logistics architectures as well as to develop a comprehensive supply chain management framework and planning tool for space logistics. The overall objective of this project is to develop an integrated capability for guiding the development of the interplanetary supply chain that will be required to enable sustainable space exploration of the Earth-Moon-Mars system and beyond.

By 2020, NASA plans to establish a long-term human presence on the moon by creating an outpost at the rim of the Shackleton crater near the lunar South Pole. To make such a scenario possible, a reliable stream of consumables such as fuel, food and oxygen, spare parts and exploration equipment would have to make its way from the Earth to the moon as predictably as any Earth-based delivery system. Or more predictably: One missed shipment could have devastating consequences when you can’t easily replenish essential supplies.

To figure out how to do that, MIT researchers Olivier L. de Weck, associate professor of aeronautics and astronautics and engineering systems, and David Simchi-Levi, professor of engineering systems and civil and environmental engineering, created SpaceNet, a software tool for modeling interplanetary supply chains.

SpaceNet is developed as a part of the MIT Space Logistics Research Project in 2005 to help NASA plan the Constellation program missions to the moon, establishing a lunar outpost. Since its inception, SpaceNet has evolved through several design iterations and has become a flexible software environment for analyzing general space exploration scenarios with respect to feasibility and establishes quantitative evaluation metrics for scenario comparison.

The system is based on a network of nodes on planetary surfaces, in stable orbits around the Earth, the moon or Mars, or at well-defined points in space where the gravitational force between the two bodies (in this case, the Earth and the moon) cancel each other out. These nodes act as a source, point of consumption or transfer point for space exploration logistics.

“Increasingly, there is a realization that crewed space missions such as the International Space Station or the buildup of a lunar outpost should not be treated as isolated missions, but rather as an integrated supply chain,” said de Weck. The International Space Station already relies on periodic visits by the space shuttle and automated, unpiloted Russian Progress re-supply vehicles.

While “supply chain” usually refers to the flow of goods and materials in and out of manufacturing facilities, distribution centers and retail stores, de Weck said that a well-designed interplanetary supply chain would operate on much the same principles, with certain complicating factors. Transportation delays could be significant—as much as six to nine months in the case of Mars—and shipping capacity will be very limited. This will require mission planners to make difficult trade-offs between competing demands for different types of supplies.

A reliable supply chain will “improve exploration capability and the quality of scientific results from the missions while minimizing transportation costs and reducing risks” to crew members, de Weck said.

SpaceNet evaluates the capability of vehicles to carry pressurized and unpressurized cargo; it simulates the flow of vehicles, crew and supply items through the trajectories of a space supply network, taking into account how much fuel and time are needed for single-sortie missions as well as multiyear campaigns in which an element or cargo shipment might have to be prepositioned by one set of vehicles or crew members while being used by another.

The manifestation of a well-structured space supply chain and logistics management would increase space travel distance and open many possibilities in space discovery. It will be the supporting system to further travel of humans to Mars or perhaps beyond. It’s not untrue if we think that logistics and supply chain is the backbone to future space discovery.

Dapatkan Konsultasi Terpersonalisasi untuk Kebutuhan Perusahaan Anda

Dapatkan Konsultasi Terpersonalisasi untuk Kebutuhan Perusahaan Anda

Jadwalkan demo dengan ahli kami untuk melihat langsung MileApp, bahas kebutuhan operasional, dan temukan paket perusahaan yang paling sesuai.

Peningkatan utilisasi kendaraan

Pengurangan waktu audit